What are the processes of the mobile phone case?

IMD

The IMD process is very popular nowadays. In essence, the film with the printed pattern is placed in a metal mold, and the TPU for forming is injected into the metal mold to bond with the film, so that the printed film is integrated with the TPU and solidified. A method of forming a product.

Features: The pattern is in the middle of the sheet (the sheet is transparent) and the TPU, so there is no possibility of being scratched and rubbed off, and the color can be kept bright for a long time without fading.

The technology can be used on TPU or acrylic mobile phone cases, and can also be plated with laser engraving, painting, glitter and other processes.

Epoxy

It is resistant to water, chemical corrosion and crystal-clear. Divided into artificial Epoxy and machine Epoxy, the best of course is artificial Epoxy, because artificial Epoxy can control the dosage well, prevent the Epoxy spilling, and achieve the effect of smoothing, but the artificial Epoxy production time is long and high cost. This phone case is on the glue, adding small jewelry, making the whole phone case more beautiful. Most mobile phone cases that use the Epoxy process will have a jelly feel. In addition to adding jewelry, you can also add glitter or gold foil decoration.

Pasting

It is a process of transferring a pattern onto a surface of a material by using a film. The specific method is to soak the water sticker in water for about 1 minute to separate the film from the paper. The film is attached to the surface of the object with an ink layer, and the toughness of the film can be utilized. Let the ink layer be attached to the phone shell material, then remove the water after drying to spray the oil to increase the feel and gloss. The product pattern can be high gloss or matt but is primarily determined by the oil sprayed and the spray technique.

Pasting production takes a long time, mainly relying on artificial stickers, so the pattern positioning of each mobile phone case is not necessarily the same. At the same time, the surface needs to be sprayed, the different oil and spraying technology are selected, and the processing fee is not the same. The quality is uneven and the prices are not the same.

Whether there is a pattern on the periphery of the product, (above) is the biggest difference between the Pasting process and the IMD process and the painting process, and this is also the biggest advantage of the water paste.

Printing

This is the simplest one of the three processes. Simply put, it is a color printer that is usually used to print the pattern on the phone case. The characteristic of this process is that there is no pattern limitation. What kind of pattern is desired to be hit immediately, the flexibility is very high, and the disadvantage is that only the front side pattern can be printed, the curved surface cannot be printed, and the uneven surface of case can be printed. The operation of painting is simple, the production is convenient, the shipment is fast, and the price is relatively cheap. Because it is printed directly, the pattern will wear out after a long time, and the pattern is relatively clear without the IMD process. The painted mobile phone case is basically matte. If you want to make a high light, you have to spray another oil, and the cost has also increased.

As an example, you can see that the edges are a bit white, that is not the pattern fading, but the result of the curved surface not printing the pattern.

UV Varnish

Matte paint

Soft paint

Painting

It is a surface coating process for industrial products, to meet the quality requirements of high temperature, friction, UV, alcohol, gasoline and other test products. The oil spray can make the monotonous product look more beautiful after being sprayed with various colors, and the life and service life of the product can be extended by an additional layer of protection.

Processing range: varnish, matte paint, soft paint.

Emboss

The embossing is also printed by the printer, and in the process of printing, the partial printing of the pattern is performed multiple times to produce the effect of embossing. There are three-dimensional and prominent feelings when you touch the touch.

Electroplating

The process of electroplating a thin layer of other metals or alloys on certain metal surfaces by electrolysis is a process of attaching a metal film to the surface of a metal or other material by electrolysis to prevent oxidation of the metal (eg, Corrosion), improve wear resistance, electrical conductivity, light reflectivity, corrosion resistance (copper sulfate, etc.) and enhance aesthetics. The mobile phone case that is added to the electroplating process is more fashionable and shiny.

Laser

Laser printing is a printing technology that uses laser ink (with metal optical color-changing anti-counterfeiting ink) and advanced laser printing technology to screen or roll laser ink on various smooth and transparent materials. The printed matter can change with observation angle. It exhibits different colors and has a distinct dynamic color-changing effect, which produces a rainbow ring effect under concentrated light.

Features: beautiful, green, environmentally friendly; resistant to ink erosion, high resistance to water vapor, carbon dioxide, etc.; laser film has high gloss for smoke, holographic layer gives film better antistatic; laser printed products are bright and eye-catching.

Quicksand

The quicksand casel is usually made of TPU material, with ordinary glittering sand, pure liquid quicksand and accessories for quicksand. Ordinary glitter silt shells can be selected from any shape and any color of sand. The quicksand shell is very popular among women, with strong mobility and special fashion.

Can be made in a variety of processes: electroplating, welt drill, anti-drop, varnish and so on.

Aurora

The Aurora process is inspired by the beautiful South and North Pole light, which is similar to the laser effect. The light changes with different angles and has a glossy feel.

Blue laser

The Blue laser mobile phone case uses TPU+IMD+ unique blue light technology. TPU is a soft material. IMD is an internationally popular surface decoration technology, surface hardened transparent film, intermediate printed pattern layer, back injection layer, ink middle, which can make products It is resistant to friction, prevents the surface from being scratched, and keeps the color bright and not fadeable for a long time, and reflects blue-violet light at different angles.

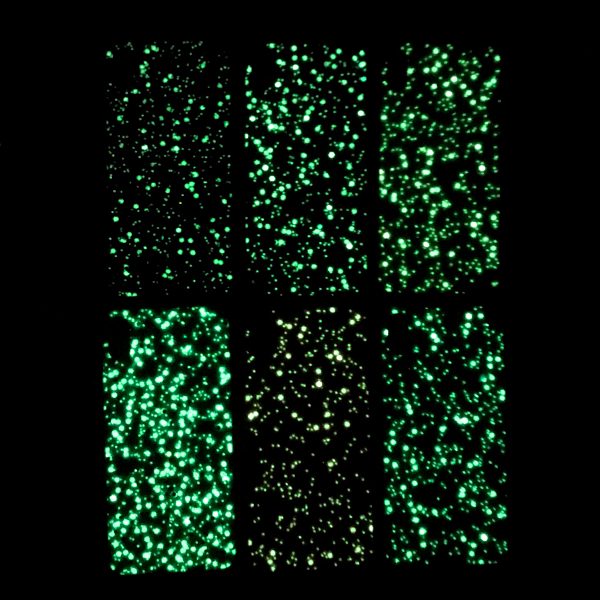

Luminous

The luminous mobile phone case belongs to a special mobile phone case, and the effect of daylight and night is different. In essence, the material of the luminous powder is added. The photo-energy storage luminous powder is a fluorescent powder that is stored after being exposed to natural light, daylight, ultraviolet light, etc., and then slowly and fluorescently after stopping the light irradiation. Released, so at night or in the dark, you can still see the glow, which lasts for hours to ten hours.

LED light (call flash)

This kind of mobile phone case with LED light is different from the previous light-emitting method. It is connected with the mobile phone through a contactor like a dust plug at the bottom, and is driven by the battery of the mobile phone. It is recognized that when a phone is tapped into the phone, it will automatically illuminate and have different colors. It is a relatively new type of mobile phone case technology. The material used is tempered glass, which will make the light brighter.

360° fully enclosed phone case

This mobile phone case is 360° covered mobile phone, in addition to the back, there is a screen, the best protection performance, all-round protection of the mobile phone, the addition of anti-drop technology, the thickness has also increased, although it will increase the size and change of the phone It’s heavy, but this kind of mobile phone case can really reduce the damage of the mobile phone.